There are many circumstances when it is necessary to model contact and contact interactions when analyzing medical implants. Such circumstances arise when devices interact with tooling, catheters, vessels and when self-contact occurs. This latter situation arises for example when a stent is crimped down tightly to catheter dimensions.

There are many circumstances when it is necessary to model contact and contact interactions when analyzing medical implants. Such circumstances arise when devices interact with tooling, catheters, vessels and when self-contact occurs. This latter situation arises for example when a stent is crimped down tightly to catheter dimensions.

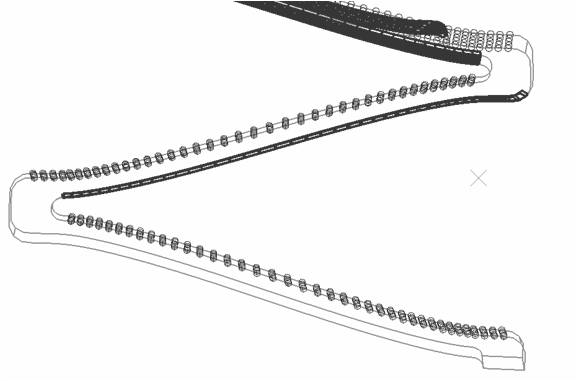

ABAQUS/Standard provides a range of methods for defining and managing contact in FEA simulations. One first defines a master surface and a slave surface which can be based on node or elements sets and/or analytically defined surfaces. Then one must select a contact interaction model and ascribe specific properties to that model. The image on the left shows both node and element sets used in a typical contact definition for self-contact of a stent.

Considerable care must be used to define appropriate surfaces. Contact interactions are computationally expensive and although ABAQUS efficiently manages their computational cost, considerations such as smoothness, consistency and other geometric factors need to be considered to maintain solution stability.

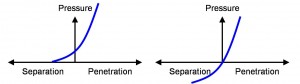

ABAQUS provides a variety of contact interaction models for mechanical contact. These include “hard†contact, “softened contactâ€, “no separation†to name just a few. Hard contact is the most simple as it simulates no reaction pressure until contact occurs then a quick ramp up as “penetration” increases. Softened contact provides a small, exponentially increasing contact pressure just prior to penetration and increasing pressure thereafter. The no separation model provides increasing pressure as penetration is increased and maintains contact with negative pressure if the surfaces attempt to move away from one another. The behavior of softened contact and no separation contact models are illustrated in the plots below.

Each of these various models have utility in simulating implantable medical devices. For example, the hard contact model and occasionally the no separation model are useful in simulating the interaction of devices with tooling during processing and manufacture and also modeling the interaction of the device with a catheter. The softened contact model is useful for simulating a device when interacting with tissue. Regardless of the model chosen, it is important to experiment with and evaluate the effects of the chosen parameters for the models. The selection of these parameters will affect the solution and therefore it is important to study such effects and verify that the results make sense for the problem being considered.

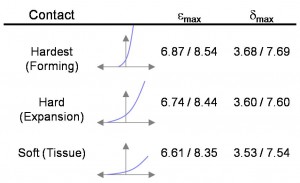

The Table below summarizes one such study using different models and sets of parameters for typical stent analysis scenarios. For this Table, a two-strut model is crimped to catheter dimensions using different contact interaction models. As much as 0.2% strain difference occurs between the hardest and the softest of the various models considered.