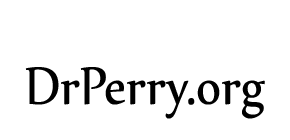

I began building my wooden boat in 1995, just after I moved to Beaverton, OR. I wanted a boat I could take out for overnight trips, either on the Williamette River or around the barrier islands off the Coast of Georgie. I had never undertaken a serious woodworking project before, so it needed to be something I could pull off on my own. The flat bottom plywood design of the Glan’L Fancy Free fit the bill perfectly. I obtained the plans and began researching my project. I read every book I could on boat biuilding, accumulated the tools I’d need and start into buying lumber and fasteners and epoxy…lots and lots of epoxy.

I’m still not done with this boat…may never be. But it has been an incredibly fun project and under the right conditions, she sails really well. I’ll introduce the boat and my project in this post, and slowly catch you up to the present…where she sits anchored off the beach ready to sail whenever I have the time.

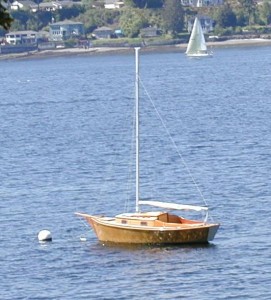

I started the project in my garage in Beaverton. Initially the plans were easy to follow: Build a form, erect the 5 frames onto the form, lay and fair the longitudinal support structures (chine, sheer clamp, keel and battens) and plank it with plywood. That gets you the bare hull built upside down and on the form. The floor was very unlevel so building the form was a challenge. In my typical fashion, I over engineered the simple 2×6 pair of beams and suffice it to say that when I pulled the hull off the form everything was within a 1/16″ of tolerance. The picture on the right shows me positioning the centerboard trunk within the frames. My sister is standing in the cabin area where there will eventually be a nice place to sleep.

I started the project in my garage in Beaverton. Initially the plans were easy to follow: Build a form, erect the 5 frames onto the form, lay and fair the longitudinal support structures (chine, sheer clamp, keel and battens) and plank it with plywood. That gets you the bare hull built upside down and on the form. The floor was very unlevel so building the form was a challenge. In my typical fashion, I over engineered the simple 2×6 pair of beams and suffice it to say that when I pulled the hull off the form everything was within a 1/16″ of tolerance. The picture on the right shows me positioning the centerboard trunk within the frames. My sister is standing in the cabin area where there will eventually be a nice place to sleep.

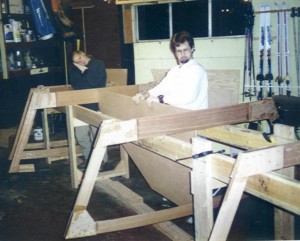

One of the best things about having built this boat are the conversations and help I’ve had from my friends. The very first trusted opinions I was fortunate to have was from Lester Lee, a fellow engineer working with me at NIKE. Lester was notorious for leveling his formidable observations about what was NOT going to work about something, but he always did so with more than a fair balance of constructive suggestions about how to fix it. Lester never complicated things and his strength as an engineer came from his simple elegance for a solution. In the picture on theleft, I believe he was telling me something about his concerns for the exposed end grain at the forward edge of the centerboard trunk.

One of the best things about having built this boat are the conversations and help I’ve had from my friends. The very first trusted opinions I was fortunate to have was from Lester Lee, a fellow engineer working with me at NIKE. Lester was notorious for leveling his formidable observations about what was NOT going to work about something, but he always did so with more than a fair balance of constructive suggestions about how to fix it. Lester never complicated things and his strength as an engineer came from his simple elegance for a solution. In the picture on theleft, I believe he was telling me something about his concerns for the exposed end grain at the forward edge of the centerboard trunk.

Another great thing about the project has been the opportunity for ingenuity and creative solving problem along the way. The plans were pretty complete, but still, it didn’t take much to force a detour into uncharted territory—like when I had to accommodate a 3/8″ thickness difference for the keelson because the only luber I could find was too thick. And of course my standards went way beyond the normal instructions. I insisted on NO BUTT JOINTS throughout the entire structure. So I scarfed every piece of lumber AND the plywood. In the picture on the right, you can see me using my beer brewing equipment to steam the keelson into shape. Not required in the formal plans, but I was certainly building what I calculated to be an unacceptable amount of residual stress into my hull!

Another great thing about the project has been the opportunity for ingenuity and creative solving problem along the way. The plans were pretty complete, but still, it didn’t take much to force a detour into uncharted territory—like when I had to accommodate a 3/8″ thickness difference for the keelson because the only luber I could find was too thick. And of course my standards went way beyond the normal instructions. I insisted on NO BUTT JOINTS throughout the entire structure. So I scarfed every piece of lumber AND the plywood. In the picture on the right, you can see me using my beer brewing equipment to steam the keelson into shape. Not required in the formal plans, but I was certainly building what I calculated to be an unacceptable amount of residual stress into my hull!

My days in Beaverton were numbered, and after two years of living and working there I had to move. I was able to just barely finish getting the hull completed so that it could be unbolted from the form and flipped right side up. Many thanks to all those who came over that night to eat Pizza Schmizza, drink a few good Oregon microbrews and picked the boat up and flipped it over. Below is what she looked like just before I left for my adventures in California.