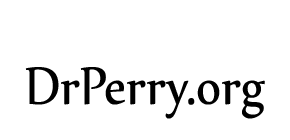

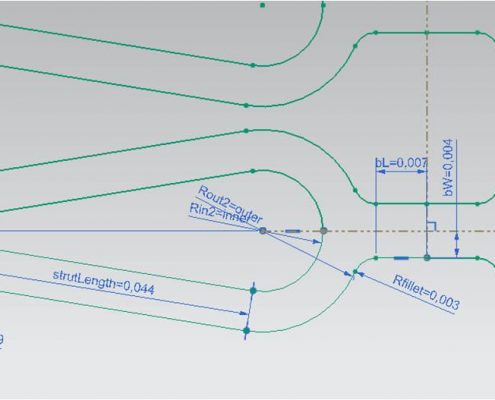

This is a simple model of the the gStent in NX. The gStent is an open source stent design developed to advance regulatory science and the use of computer models and simulations in making safe and effective medical products. Building the model in NX was easy. After importing the sketch geometry, it took only a few steps to create the intelligence and dimensions required to drive the model.

The full gStent-BE model has only four or five driving dimensions plus a few material and manufacturing parameters that define the entire product. The effects of electropolishing, for example, can be turned on or off or adjusted based on process observations as an independent feature in the design tree. NX even has an “idealized part” mode, perfect for commercial FEA users who want to leverage existing simulations and results by demonstrating equivalence to related products.

There are at least three ways in NX to convert between the flat and wrapped version of the geometry:

Sheet Metal Bend

The Sheet Metal Bend method is a method we’ve seen used many times with SolidWorks. It was quickly abandoned in NX for other, much better approaches.

Global Shaping

Global Shaping is a very general and powerful feature in NX. In this method, you create a reference curve—the profile can be a nearly complete arc, arbitrary spline, whatever you want—as long as it is the same length as your base sketch reference line, Global Shaping will wrap your geometry to that profile. It’s easier to build the flat pattern geometry as an extrusion, but like the Sheet Metal Bend the method requires leaving a small gap that requires closing, adjusting of tolerances and other unnecessary sketch maintenance .

Wrap Curve

The Wrap Curve was the most direct approach, the easiest to implement and it worked best with the intelligence of the model for the design intent. Wrap Curve functions similarly to Global Shaping, but with Wrap Curve we can use a whole circle for the reference curve and there isn’t any fussing with gaps and tolerances.