With the growing use of Nitinol in medical implants, there is a need for improved characterization of the material behavior of Nitinol and methodologies for better product design and engineering. While it is a good starting point, the typical approach of employing the force-deformation response from uniaxial tension tests for input and validation of material models is rather limited. In particular, the ambiguities associated with the global versus local stress strain curve make the interpretation of finite element analysis non-trivial.

With the growing use of Nitinol in medical implants, there is a need for improved characterization of the material behavior of Nitinol and methodologies for better product design and engineering. While it is a good starting point, the typical approach of employing the force-deformation response from uniaxial tension tests for input and validation of material models is rather limited. In particular, the ambiguities associated with the global versus local stress strain curve make the interpretation of finite element analysis non-trivial.

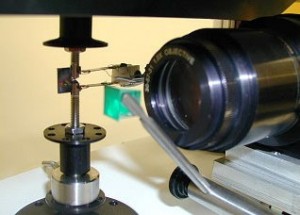

To address these concerns, we’ve developed sophisticated methods in our laboratory to study the initiation of cracks in Nitinol. We have studied closely fatigue loading of carefully designed coupon samples to differentiate between cracks forming in austenite, martensite and mixed phase conditions. Usisng closed loop cyclic loading and real time interferometric measurements we continue to make advances in understanding the complex fatugue behavior of implantable metal alloys.