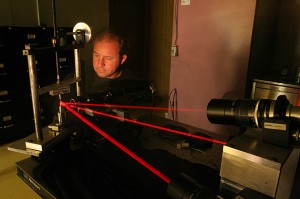

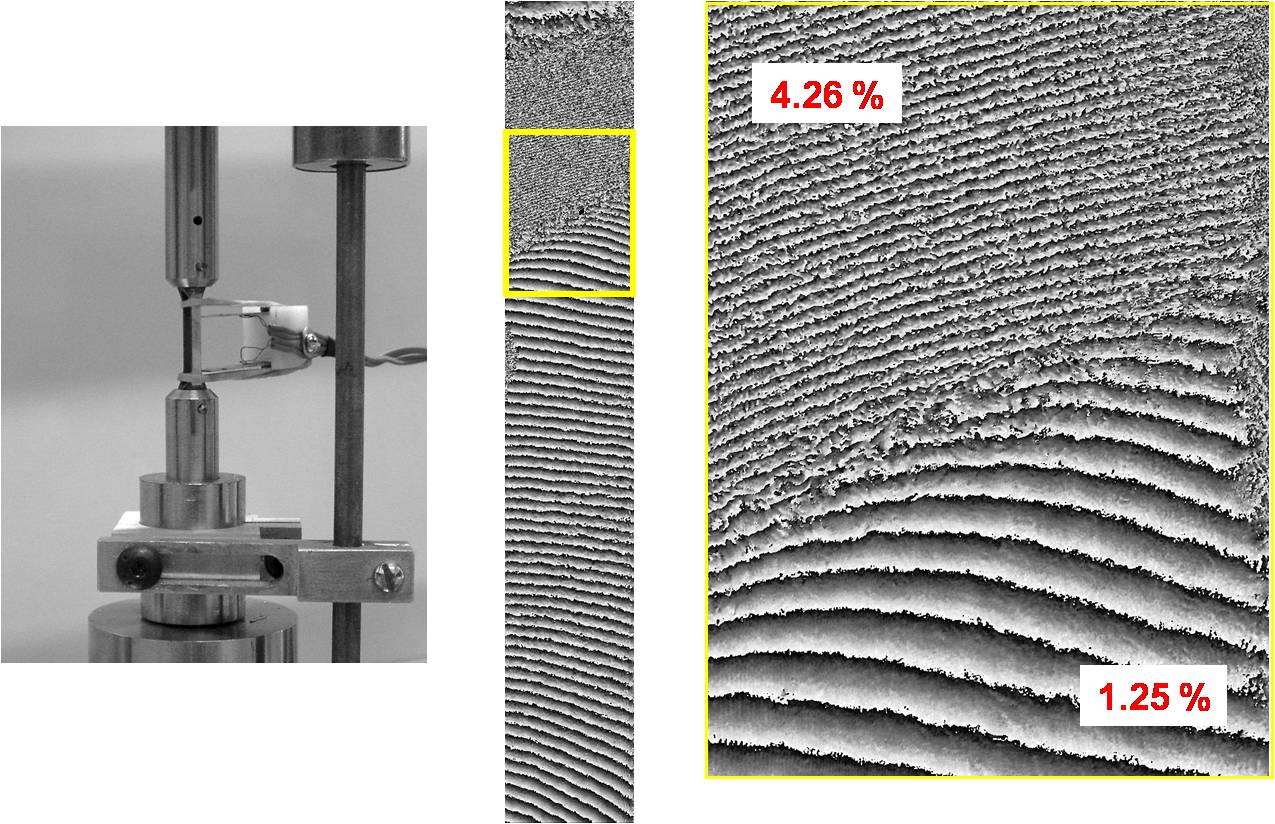

We dusted off the interferometer recently to perform some new experiments on Nitinol. The photo on the left shows our four beam phase shifted moire intereferometer trained on a Nitinol tension sample in a simple hand operated load frame. We had our expert photographer Andy on hand and took quite a few long exposure photos with beam traces.

Our current experiments are part of our ongoing effort to better characterize Nitinol material behavior for use with Finite Element Analysis codes. For our most recent experiments, we were interested in investigating the evolution of hysteresis loops after different types and amount of preconditioning. We are doing this for both tension and in bending to see how well our user material subroutine handles residual inelasticity with load reversals.

We’re also doing similar experiments for stainless steel and cobalt chrome, two other materials commonly used in medical implants. Our goal is to improve the state-of-the-art in computer modeling and advance engineering methods for validating implantable medical devices. Using our advanced interferometric techniques, we can make measurements on coupon samples as well as implantable components.