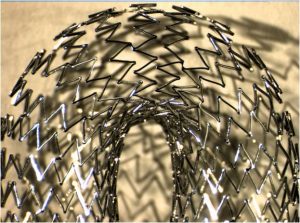

The 6F LifeStent NT is an implantable self-expanding nickel titanium alloy (Nitinol) stent. The stent is manufactured from small diameter Nitinol tubing and is loaded into a delivery catheter for placement/deployment into a vessel.

The stent is based on a helical design which offers a wide range of performance advantages when compared to stents with circumferential hoops. The helix pattern is inherently more flexible than circumferential hoop designs because a helix has an additional degree of flexibility (torsion) with respect to longitudinal bending. This additional degree of freedom imparts a high degree of kink resistance and enables the helical stent to maintain excellent wall apposition under the combined effects of bending, twisting and stretching.

The LifeStent NT achieves this enhanced flexibility while maintaining the same radial force characteristics as similar 6F circumferential designs manufactured from Nitinol tubing. This is possible because radial stiffness and chronic outward forces depend primarily on the dimensions of the struts and the helical design dictates only the patterns of connections, or bridges, between the struts. The LifeStent NT therefore combines the flexibility benefits of a helical architecture and the radial force and tight mesh density of a Nitinol tubing stent.

The LifeStent NT achieves this enhanced flexibility while maintaining the same radial force characteristics as similar 6F circumferential designs manufactured from Nitinol tubing. This is possible because radial stiffness and chronic outward forces depend primarily on the dimensions of the struts and the helical design dictates only the patterns of connections, or bridges, between the struts. The LifeStent NT therefore combines the flexibility benefits of a helical architecture and the radial force and tight mesh density of a Nitinol tubing stent.

I’ve also included here a link to the patent that describes a highly flexible stent having a central helical wound portion, and another link to a patent that describes the bridges and the transition zone utilized in the Lifestent NT.